Top Oil Seal Manufacturers: Understanding Quality and Reliability in Diesel Engine Parts

The performance and longevity of diesel engines heavily depend on multiple components, among which oil seals play a critical role. In this comprehensive guide, we will delve into the world of oil seal manufacturers, exploring their importance, the manufacturing process, and the key factors to consider when sourcing these essential parts for your diesel engines.

What are Oil Seals and Why Are They Important?

Oil seals, also known as shaft seals or lip seals, are mechanical components that prevent the leakage of lubricants and fluids from various machinery. In the context of diesel engines, these seals maintain optimal operating conditions by:

- Preventing Fluid Leakage: Oil seals ensure that lubrication remains within the engine, thus protecting it from wear and tear.

- Reducing Contamination: They restrict dirt and other contaminants from entering the critical engine parts.

- Enhancing Efficiency: Proper sealing helps in maintaining pressure and improves the overall efficiency of the engine.

The Role of Oil Seal Manufacturers

The relevance of oil seal manufacturers cannot be overstated. These manufacturers are crucial in producing high-quality seals that meet essential standards and specifications for diesel engines. Here are some reasons highlighting their significance:

- Quality Control: Reliable manufacturers implement strict quality control measures to ensure each product meets or exceeds industry standards.

- Material Selection: The best manufacturers use high-grade materials such as rubber and PTFE to fabricate oil seals that can withstand extreme conditions.

- Innovative Solutions: Leading companies invest in research and development to create innovative seal designs that address specific application challenges.

Factors to Consider When Choosing Oil Seal Manufacturers

When sourcing oil seals for diesel engines, it is vital to assess potential manufacturers based on several key criteria:

1. Product Range and Specialty

Consider whether the manufacturer offers a variety of seals designed for different applications. A specialized oil seal manufacturer can provide tailored solutions for unique engine requirements, ensuring better compatibility and performance.

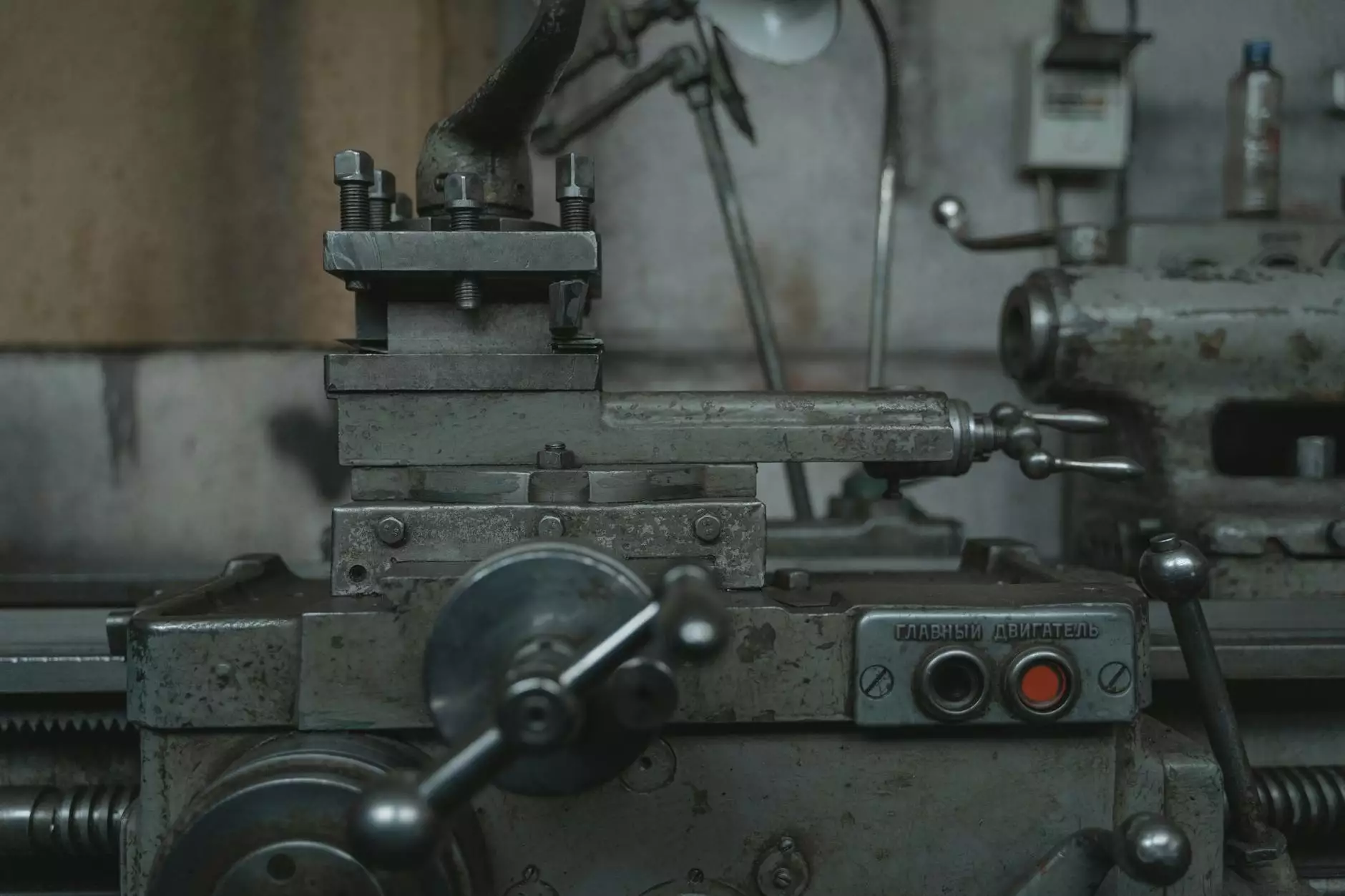

2. Manufacturing Processes

Explore the manufacturing processes employed by the company. Advanced techniques, such as injection molding and automated production lines, often result in superior-quality products.

3. Certifications and Standards

Check if the manufacturer complies with international standards such as ISO 9001. Certifications are indicators of operational excellence and product reliability.

4. Customer Reviews and Reputation

Researching customer testimonials can offer insights into the manufacturer's reliability, product performance, and level of customer service. A positive reputation among peers and customers is a good sign of quality.

5. Technical Support and After-Sales Service

Evaluate the level of technical support provided. Many top-tier manufacturers offer extensive after-sales service and assistance that can help ensure the right product is selected and properly installed.

Highlighting Notable Oil Seal Manufacturers

While there are numerous manufacturers across the globe, some stand out due to their exceptional quality and service. Here are a few notable oil seal manufacturers recognized for their contributions to the industry:

1. Client Diesel

Client Diesel, featured at client-diesel.com, is a prominent player in the diesel engine parts sector. They provide a comprehensive range of oil seals designed specifically for diesel applications, ensuring compatibility and enhanced performance. Their commitment to quality and innovation positions them as a trusted supplier of spare parts.

2. SKF

SKF is a global leader in bearing technology and oil seals. Known for their robust designs and ability to cater to various industrial needs, they utilize advanced materials that enhance seal longevity and reliability. Their extensive catalog includes seals for diverse applications, including automotive and industrial machinery.

3. Parker Hannifin

Parker Hannifin offers a wide range of sealing solutions, including oil seals that are critically acclaimed for their effectiveness. Their focus on engineering excellence and customer-centric designs makes them a formidable competitor in the sealing market.

4. Federal-Mogul

Federal-Mogul is renowned for its diverse array of engine components, including high-performance oil seals. Their products are designed to withstand rigorous operating conditions, making them ideal for heavy-duty diesel engines.

Understanding the Manufacturing Process of Oil Seals

The journey of an oil seal from raw materials to a finished product involves several intricate steps. Here’s a detailed look at the manufacturing process:

1. Material Selection

The first step involves selecting appropriate materials that provide the right balance of flexibility, durability, and heat resistance. Common materials include:

- Rubber compounds

- Polyurethane (PU)

- Polytetrafluoroethylene (PTFE)

2. Molding

Once materials are selected, they are subjected to molding processes. The two predominant methods are:

- Compression Molding: Molding involves placing material in a heated mold, where it is subjected to pressure to achieve the desired shape.

- Injection Molding: Material is injected into a mold under high pressure, allowing for more complex shapes and finer details.

3. Curing

The molded seals undergo a curing process where heat is applied to solidify the materials and enhance their hardness and elasticity.

4. Quality Control

Throughout the production process, quality control measures are essential. Each batch of seals undergoes rigorous testing for defects and performance metrics.

5. Packaging and Distribution

Finally, after passing quality checks, the seals are carefully packaged and distributed to customers. Proper packaging is crucial to protect the seals from damage during transport.

Tips for Maintaining Oil Seals in Diesel Engines

Proper maintenance of oil seals can significantly enhance their lifespan. Here are some expert tips:

- Regular Inspections: Check seals for signs of wear, protrusion, or damage regularly to prevent costly leaks.

- Use Quality Fluids: Ensure that the lubricants used are of high quality and compatible with the seals to avoid degradation.

- Monitor Engine Temperature: Excessive heat can lead to premature seal failure, so maintaining optimal operating temperatures is essential.

- Avoid Contaminants: Keep the engine and surrounding areas clean to minimize the risk of dirt and debris compromising seal integrity.

- Professional Installation: Always have seals installed by professionals to ensure correct placement and avoid damaging them during installation.

Conclusion

Understanding the importance of oil seal manufacturers and the intricacies involved in producing quality oil seals can greatly enhance your engine's performance. From selecting reliable manufacturers like Client Diesel to understanding their manufacturing processes and maintenance, this guide serves as a comprehensive resource for anyone involved in sourcing diesel engine parts. By choosing the right seals and maintaining them correctly, you can ensure that your diesel engines operate efficiently and reliably for years to come.