Unparalleled Metal Fabrication Services for Precision CNC Lathe Turning Parts at DeepMould.net

In today's highly competitive manufacturing landscape, the ability to produce high-quality, precision-engineered components efficiently is paramount. As industries evolve, so does the demand for sophisticated metal fabrication solutions capable of delivering intricate parts with impeccable accuracy. At DeepMould.net, we specialize in providing comprehensive metal fabricator services, specializing in the production of cnc lathe turning parts that meet the highest industry standards.

The Importance of Specialized Metal Fabrication in Modern Industry

Metal fabrication forms the backbone of numerous sectors, including aerospace, automotive, medical devices, electronics, and heavy machinery. Precision components such as cnc lathe turning parts are critical to ensuring the proper functioning, safety, and longevity of industrial equipment. High-quality fabrication not only enhances product performance but also reduces maintenance costs and operational downtimes.

Why Choose DeepMould.net for Your CNC Lathe Turning Parts Needs?

- Expertise & Experience: Our team possesses extensive experience in metal fabrication, specializing in complex cnc lathe turning parts manufacturing.

- Advanced Technologies: We employ state-of-the-art CNC turning centers, lathe machines, and precision measuring tools to guarantee extraordinary accuracy.

- Quality Assurance: Rigorous quality control procedures ensure each component meets strict dimensional and surface finish standards.

- Customization & Flexibility: We cater to bespoke engineering requirements, offering tailor-made solutions for unique project specifications.

- Competitive Pricing & Fast Turnaround: Our optimized workflows allow us to deliver high-quality results within budget and on time.

The Process of Manufacturing Premium cnc lathe turning parts

1. In-Depth Consultation & Design Optimization

Every successful manufacturing project begins with a thorough understanding of client needs. Our engineers work closely with you to analyze design files, suggest improvements for manufacturability, and recommend material choices conducive to durability and cost-effectiveness.

2. Material Selection

We offer a broad spectrum of materials, including stainless steel, aluminum, brass, copper, titanium, and specialty alloys. The right material selection is crucial for achieving optimal performance, corrosion resistance, and thermal stability for your cnc lathe turning parts.

3. Precision Machining

Utilizing advanced CNC lathe machines, we perform high-precision turning to create components with tight tolerances—often within ±0.005mm. Our machines support complex geometries, fine threading, and intricate surface finishes, ensuring your parts meet exact specifications.

4. Surface Finishing & Quality Control

Post-machining, parts undergo surface finishing processes such as polishing, coating, and anodizing, enhancing both appearance and resistance to wear. Our dedicated quality control team implements comprehensive inspections, including coordinate measuring machine (CMM) analysis, to verify dimensional accuracy and surface quality.

Technical Advantages of Our CNC Lathe Turning Parts Manufacturing

- Exceptional Tolerance Control: Achieve micron-level precision vital for critical engineering applications.

- Complex Geometries: Capable of producing complex, multi-faceted parts with smooth contours and detailed features.

- Material Versatility: Support for diverse metals and alloys to match specific performance criteria.

- Scale Flexibility: From prototype runs to large-scale production, we adapt seamlessly to your project size.

- Consistent Quality: Single-source manufacturing ensures uniformity in batch runs, minimizing variability.

Industry Applications of cnc lathe turning parts

The applications of our cnc lathe turning parts span numerous high-demand industries. Here are some key sectors benefiting from our precision manufacturing:

Aerospace & Defense

Components requiring high strength-to-weight ratios, corrosion resistance, and exacting tolerances, such as turbine shafts, landing gear parts, and fasteners.

Automotive

Engine components, transmission parts, and custom fasteners that demand durability and precision assembly.

Medical Devices

Micro-machined parts with precision finishes, including implants and surgical tools, where exact measurements and high-quality surface finishes are critical.

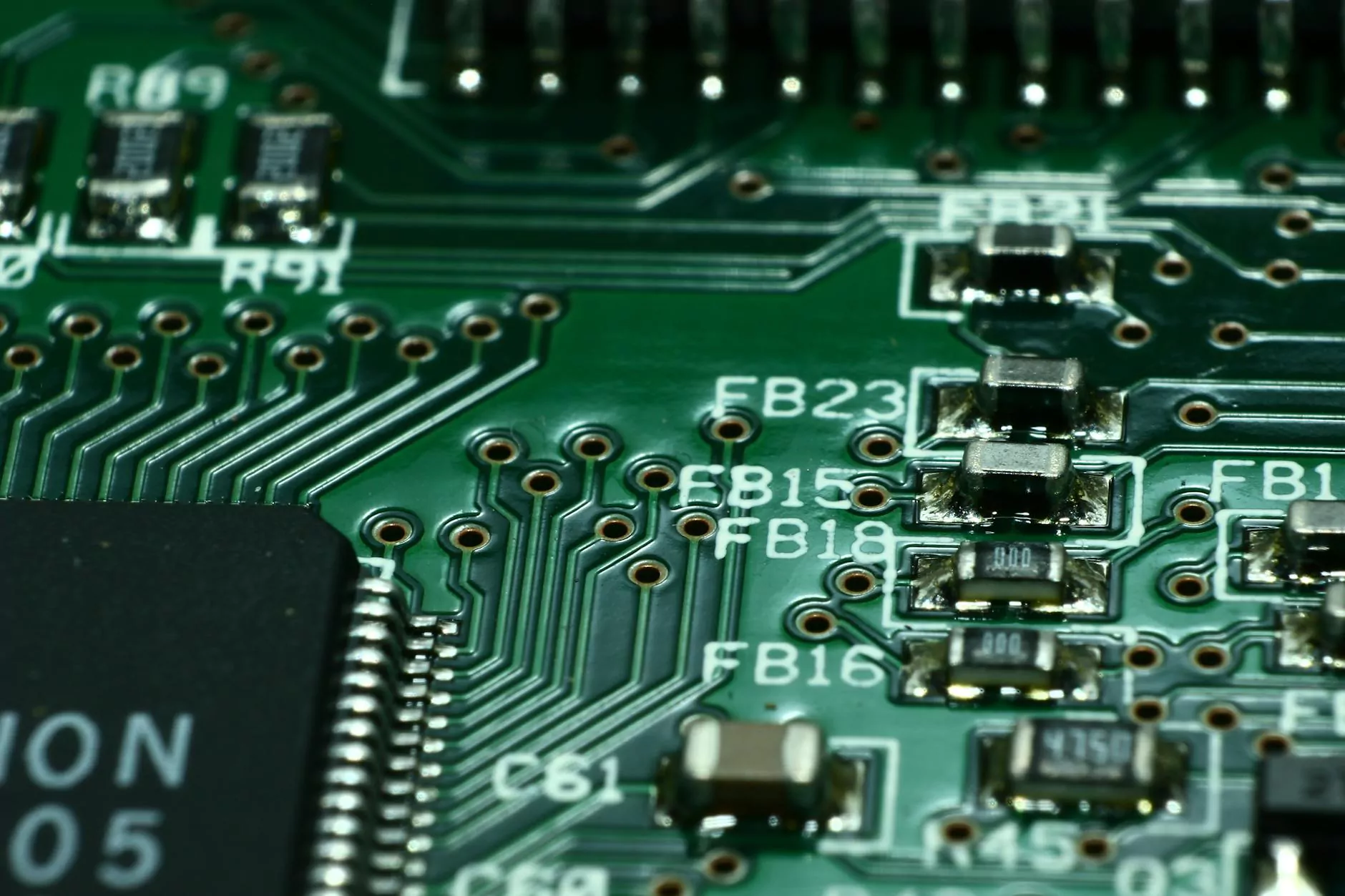

Electronics & Semiconductor

Thermal management components, connectors, and housings that require precise dimensions and reliable performance under strict standards.

Heavy Machinery & Industrial Equipment

Wear-resistant, robust parts such as shafts, bushings, and mounting hardware designed for demanding environments.

The Commitment to Sustainability and Innovation

At DeepMould.net, we recognize the importance of sustainable practices and continuous process innovation. Our facilities incorporate eco-friendly materials, waste reduction strategies, and energy-efficient machinery. Additionally, ongoing investment in R&D enables us to stay at the forefront of technology, ensuring that our cnc lathe turning parts are not only of premium quality but also produced responsibly.

Partner with DeepMould.net for Your Metal Fabrication and CNC Turning Projects

Choosing the right manufacturer is crucial for achieving your project goals efficiently and economically. With our comprehensive capabilities, commitment to quality, and customer-centric approach, DeepMould.net is your ideal partner for all metal fabricator needs, especially specialized cnc lathe turning parts.

Contact Us Today for Custom Metal Fabrication Solutions

Our team is ready to assist you in developing custom cnc lathe turning parts that meet your unique specifications. Reach out to DeepMould.net today to discuss your project, request a quote, or learn more about our advanced manufacturing capabilities. Let us turn your innovative ideas into tangible, high-quality metal components that drive your success forward.